Epson launches partnership and Smart Factory with Citizen Wolf and collaboration with OzHarvest Ventures

Supporting sustainable manufacturing and minimising waste in the fashion and food industries

Epson officially launched their partnership and shared goal with Citizen Wolf of minimising waste in the fashion and manufacturing space. The two companies have also collaborated to create a Smart Factory that combines Citizen Wolf’s made to order technology with Epson’s cutting edge direct-to-garment printing technology.

(l-r) Epson A/NZ MD Craig Heckenberg, OzHarvest founder Ronni Kahn and Citizen Wolf co-founder Eric Phu

Epson and Citizen Wolf also took the opportunity to launch a limited-edition range of sustainably produced t-shirts and tote bags in collaboration with OzHarvest Ventures, the social enterprise entity of OzHarvest, where proceeds from products sold support OzHarvest’s work delivering meals to people in need.

Eliminating waste is something all three brands firmly believe in and have as a core branding pillar.

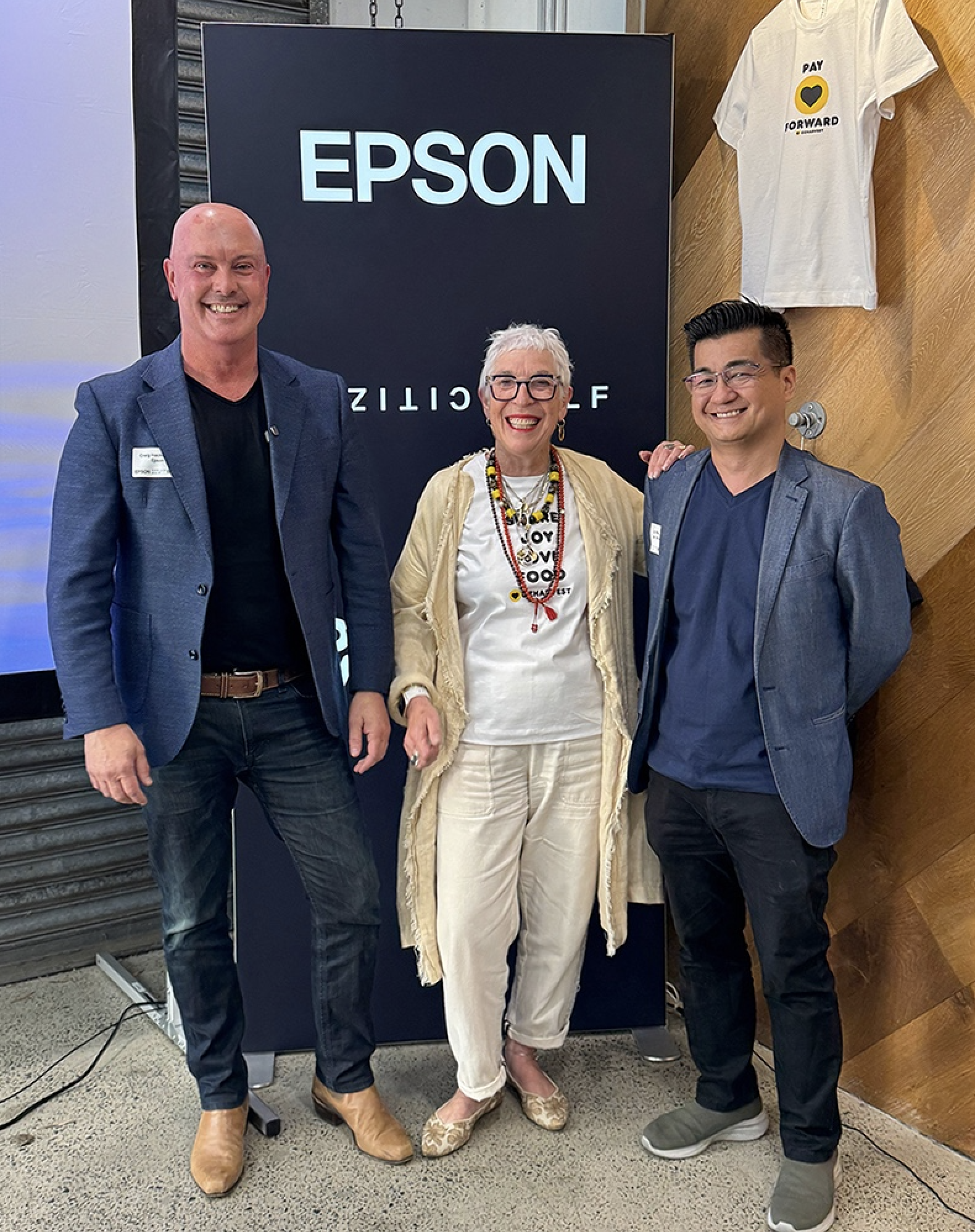

Epson A/NZ MD Craig Heckenberg with the Epson SureColor F2260

Epson A/NZ MD Craig Heckenberg explained, “The NSW Government’s recent EPA report notes that 400,000 tonnes of textile waste alone is landfilled in Australia every year. Our partnership with Citizen Wolf, the creation of the Smart Factory and our support of the OzHarvest Ventures social enterprise initiatives are of particular value to the environment as they significantly contribute to our shared goals around sustainable manufacturing and minimising waste in the fashion and food industries.”

Citizen Wolf is Ethical Clothing Australia accredited and B Corp certified, ensuring that every garment meets the highest sustainability and ethical standards and is 100% made in Australia – all of which were demonstrated at last night’s launch event in their Marrickville factory.

Citizen Wolf co-founder Eric Phu explaining the Smart Factory manufacturing process

Citizen Wolf co-founder Eric Phu explaining the Smart Factory manufacturing process

Citizen Wolf co-founder Eric Phu added, “In collaborating with Epson to create a smarter factory we’re able to bring to life a new innovation with our Zero Inventory Merchandise (ZIM) solution. This solves the real-world problem of eliminating the financial risks and incredible waste inherent in the fashion and merchandise industry, by combining Citizen Wolf's and Epson's leading on-demand technologies.”

(l-r) Epson A/NZ MD Craig Heckenberg, Epson A/NZ corporate marketing manager Priscilla Dickason, OzHarvest founder Ronni Kahn and Citizen Wolf co-founder Eric Phu with items from the new OzHarvest range printed on the Epson F2260 in the new Smart Factory at Citizen Wolf

Typically charities and brands would need to order and pay for mass quantities of merchandise in advance, without knowing which style, designs or sizes will sell well resulting in unsold stock wasting money and resources. For charities in particular this ties up their finances in warehousing items rather than being used to deliver on their mission.

Phu continued, “The ZIM solution flips this model by allowing charities and other brands to have custom made garments, hold zero inventory, get their money upfront from the customer and only pay for what they sell. In this way they can create as many designs, styles and sizes of garments as they wish that are only produced when an order is placed. It eliminates the capital and risks associated with holding inventory so it can be focused on supporting their charitable work, while creating new revenue streams to support their fundraising activities.”

Heckenberg added, “Given the enormous amounts of clothing sold during Black Friday and the holiday gifting season, most of which ends up in landfill within the year, the new smart factory and ZIM model are much needed and far more efficient alternatives that are better for people, charities and the planet.”

In order to create the Smart Factory Epson has provided their significant printing expertise and several pieces of key equipment including their SureColor F2260 A3+ DTG/DTFilm (direct-to-garment and direct-to-film) fabric and merchandise printer, a D300 Speed Oven and a SEFA Rotex Pro Swing Away Heat Press.

OzHarvest Ventures is the newly established social enterprise and profit-for-purpose sister entity to OzHarvest, launching business ideas that help people and planet. OzHarvest was founded in 2004 by Ronni Kahn AO and has since become a leading national food rescue organisation on a mission to ‘Nourish our Country’ by stopping good food going to waste and delivering it to charities that help feed people in need.

When announcing their support for the latest range Heckenberg added, “OzHarvest is a wonderful for-impact organisation that helps stop food waste and feed those doing it tough in our community. We are delighted to work together with Citizen Wolf to print a range of t-shirts, tote bags and aprons, featuring designs by OzHarvest’s founder Ronni Kahn in the new Smart Factory. Proceeds from the range will support OzHarvest to carry out their amazing and impactful work.”

OzHarvest founder Ronni Kahn commented, “My designs feature symbols of hope and collective action we can all take to do good in the world. This unique showcase is an example of how we can all work together and create positive impact for the world through innovative ideas and collaboration.”

The new range is available for purchase exclusively from shop.ozharvest.org

More about Epson’s SureColor F2260 A3+ DTG/DTFilm fabric and merchandise printer

Epson’s SureColor F2260 printer is a key model in their highly successful DTG (direct-to-garment) range.

The F2260 has a host of features that make it fast and efficient while also enhancing support for the increasingly popular DTF (direct-to-film) production workflow.

The F2260 combines a proven production platform with upgraded componentry, enhanced ergonomics and high-quality UltraChrome DG2 ink which has been designed to support a wider range of fabrics with better colour and less bleed. The new ink is also compatible with DTF workflows.

Epson’s SureColor F2260 A3+ DTG/DTFilm fabric and merchandise printer

True to Epson’s continued commitment on sustainability, the F2260 incorporates a number of features to reduce waste and expense. It uses 800 ml ink pouches that are not only 33% larger than previous pouches but also incorporate a lot less plastic than the cartridges previously used. The printer has also dispensed with a fan for quieter operation without the need for regular filter replacement.

As with its predecessor, the F2260 incorporates a head that doesn’t require regular replacement which means productivity is maximised while parts and labour costs are significantly reduced and e-waste is kept to a minimum.

For more information on the SureColor F2260 A3+ DTG/DTFilm fabric and merchandise printer go to: www.epson.com.au/products/large-format-printers/dtfilm-and-dtg/surecolor-f2260